Timber systems

For more than 30 years, Moretti has been active in the timber construction sector, completing all types of projects: residential, commercial, offices, industrial, sports and tourist accommodation.

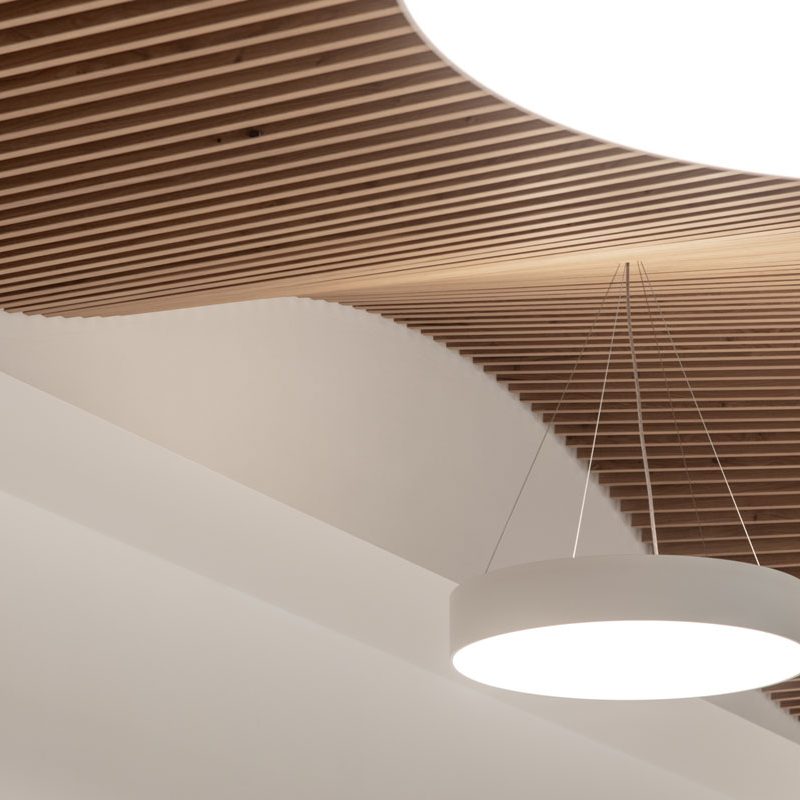

Glulam

Glued laminated timber (glulam) is an extremely versatile material that combines excellent mechanical properties with extremely lightweight structures, without foregoing the aesthetic value. Warmth, comfort and sustainability for forward-looking structures.

Technology behind the scenes at the Moretti Modular Contractor site

Lamination technology is based on the splitting of spruce logs or larch-wood into planks of predefined sizes, which are then selected visually or mechanically to identify and eliminate local imperfections (knots, resin pockets, etc.).

The structural element is produced by gluing the planks together (finger joint) end-to-end, so as to obtain individual layers of potentially infinite length; these layers are then glued together along the longer side (base of the finished element) using adhesives that guarantee strength and durability.

Therefore, by eliminating the imperfections and reconstructing the element, we can obtain “artificial” structural members with cross-sections and lengths greater than those of original pieces of timber,

while also guaranteeing superior mechanical properties depending on the degree of selection of the planks (resistance classes regulated by EN 14080:2013).

Moretti Modular Contractor is one of the few companies in Italy that produces its own glued laminated timber; at our Erbusco site, we make even the most ambitious project a reality.

Moretti’s 30+ years of experience in the industry makes it the ideal partner with whom to share and develop architectural projects and ideas.

Our rich portfolio of projects, of all different sizes, can be found all over Italy, from Trentino to Sicily and Sardinia, and from Piedmont to Friuli Venezia Giulia, including new construction projects, functional extensions, architectural renovations and structural upgrading.

The production process of laminated wood

Moretti is one of the few producers of laminated wooden elements capable of containing all production phases within the company, from raw materials to finished products ready to be assembled. This is possible thanks to a facility that combines two elements: the mechanical equipment necessary for automated processing and manual labor. The production chain is able to work curved beams in monoblock starting from individual lamellae of 4 cm thickness. The spans can reach up to 49 meters depending on the radius of curvature, the heights exceed 240 cm. For increased width, the thickness can be increased by combining two or three beams glued on the side. A set of skills that allows meeting different market needs, especially concerning shaped beams.

What are the advantages of building with Moretti Modular Contractor glulam?

Sustainability

Timber constructions are the sustainable answer to the demands of modern living. Glulam production is low energy and it is renewable if obtained from a forest management system that meets the strictest standards, such as FSC and PEFC.

Versatility

Glulam structures can be adapted to all structural and architectural requirements.

There are limitless possibilities in shapes and spans that can be designed and manufactured using glulam, thanks to the elements produced directly by Moretti.

Lightweight

Slim and lightweight structural elements improve the seismic performance of the structure, in addition to ensuring easier handling, where a minimal impact on the weight of the work is necessary.

Industrialisation

Internal production allows for the production of state-of-the-art elements, certified by stringent checks on the quality of the finished product. The application of numerical control guarantees low risk of errors and short assembly times.

Engineering

Moretti is not only a timber manufacturer. Each element is engineered by the internal technical department, which uses its many years of experience to ensure the best solution both technically and economically.

Design

A timber structure can alone give life and aesthetic value to a building. The numerous solutions are adaptable to meet the aesthetic demands of both customers and engineers. No more structures hidden with boring cladding.

Comfort

Choosing glulam for construction means a more healthy overall environment.

Glulam provides warmth, comfort, optimising naturally the temperature and humidity of the room.

Fire resistance

Glulam ensures significant fire resistance (up to R120′) due to the capacity to be consumed without losing its mechanical properties. No treatment or protection is required.

Our certifications

FSC® (Forest Stewardship Council®) is a certification scheme that guarantees for consumers that the product is made from material sourced from forests managed properly from an environmental, social and economic point of view.

Moretti Modular Contractor uses timber from responsibly managed forests with FSC® certification.

Search our FSC® certified products.

PEFC™ is the Programme for Endorsement of Forest Certification Schemes. Moretti Modular Contractor uses timber from responsibly managed forests with PEFC™ certification.

What Moretti Modular Contractor designs, produces and creates in glulam

NON CANCELLARE

We can create beams with standard and non-standard shapes, straight beams, curved beams and generic variable heights: we design and create our own products

Layer thicknesses: 33 mm (Rmin = 7.00 m) / 40 mm (Rmin = 8.50 m)

(different thicknesses on request)

Element bases: 10-12-14-16-18-20-22-24 cm (26 cm on request)

Element heights: from 8 cm to 252 cm

Length limit: max. 42.0 m

Resistance classes: GL24h / GL28c / GL28h (GL30c / GL32c on request)

Through the composition of monolithic elements using joinery techniques, we create composite systems with no limits in size and shape. There is always a suitable solution for every structural and functional problem

The versatility, aesthetics and lightness of timber combined with the solidity of concrete to create roofs and floors that are beautiful to behold and structurally high-performance.

We use glulam to produce pre-assembled framed panels that can be used untreated as a framework for roofs, puter walls or downstands, or complete with insulation and sealing as structural elements for roofs, floors or structural walls. From untreated to finished, we can cover any surface area.

X-Lam Structures

In addition to glulam structures, Moretti also designs and builds X-lam structures. From floors to roofs and walls, Moretti’s single-storey and multi-storey buildings are designed and built for any intended use.

Façade structures and cladding

Moretti’s know-how is not just about bare structures. Timber can be used to create frames for glass walls or to clad structures of all kinds, giving each work added aesthetic and architectural value.

Roof insulation packages

Roofs are and remain Moretti’s starting point, where it all began. Timber-based roof insulation packages are ideal for completing a roof structure.

Whether it is a warm or a ventilated roof insulation package, Moretti provides its expertise to ensure maximum aesthetic value and functional comfort of the finished work.