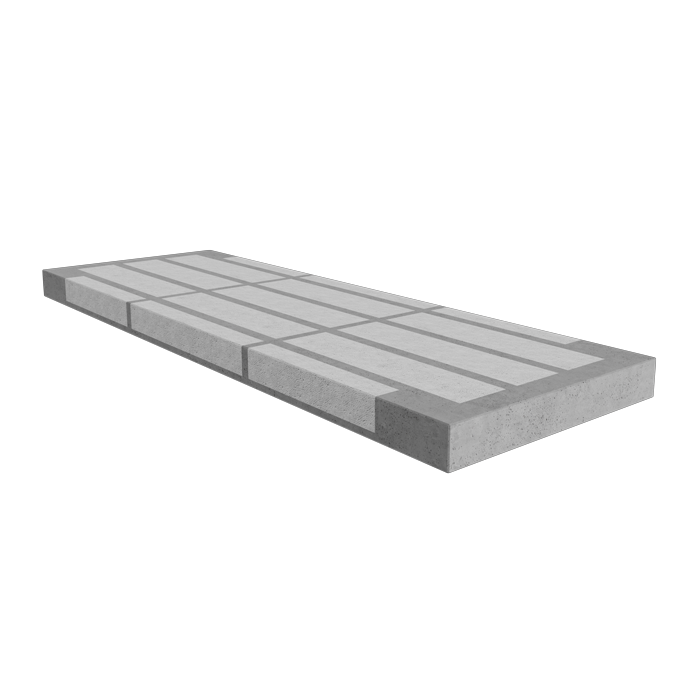

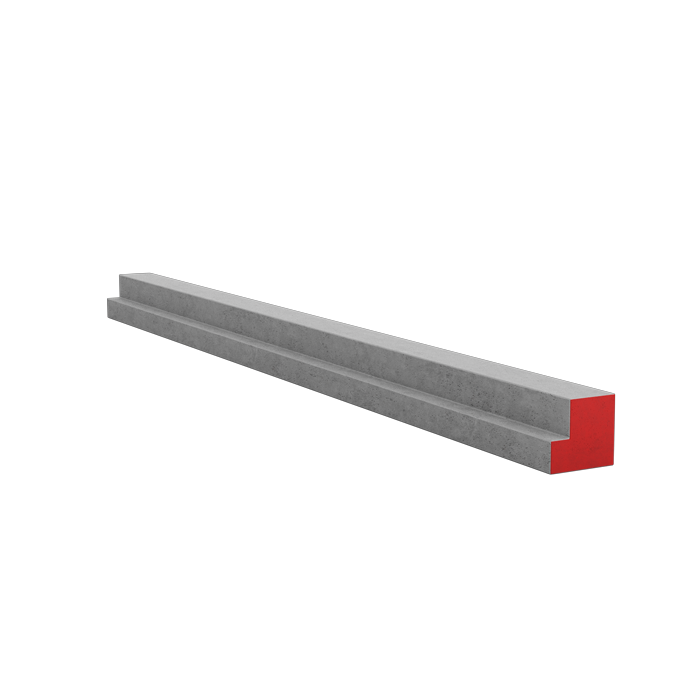

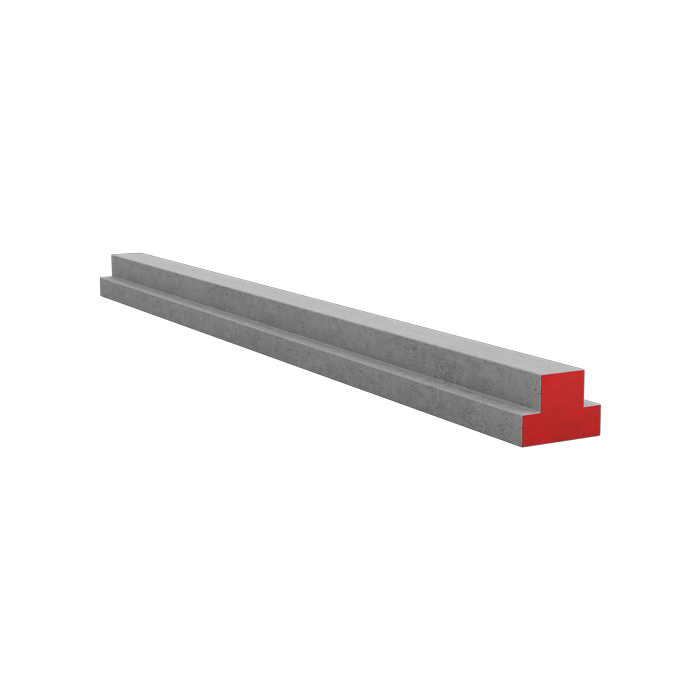

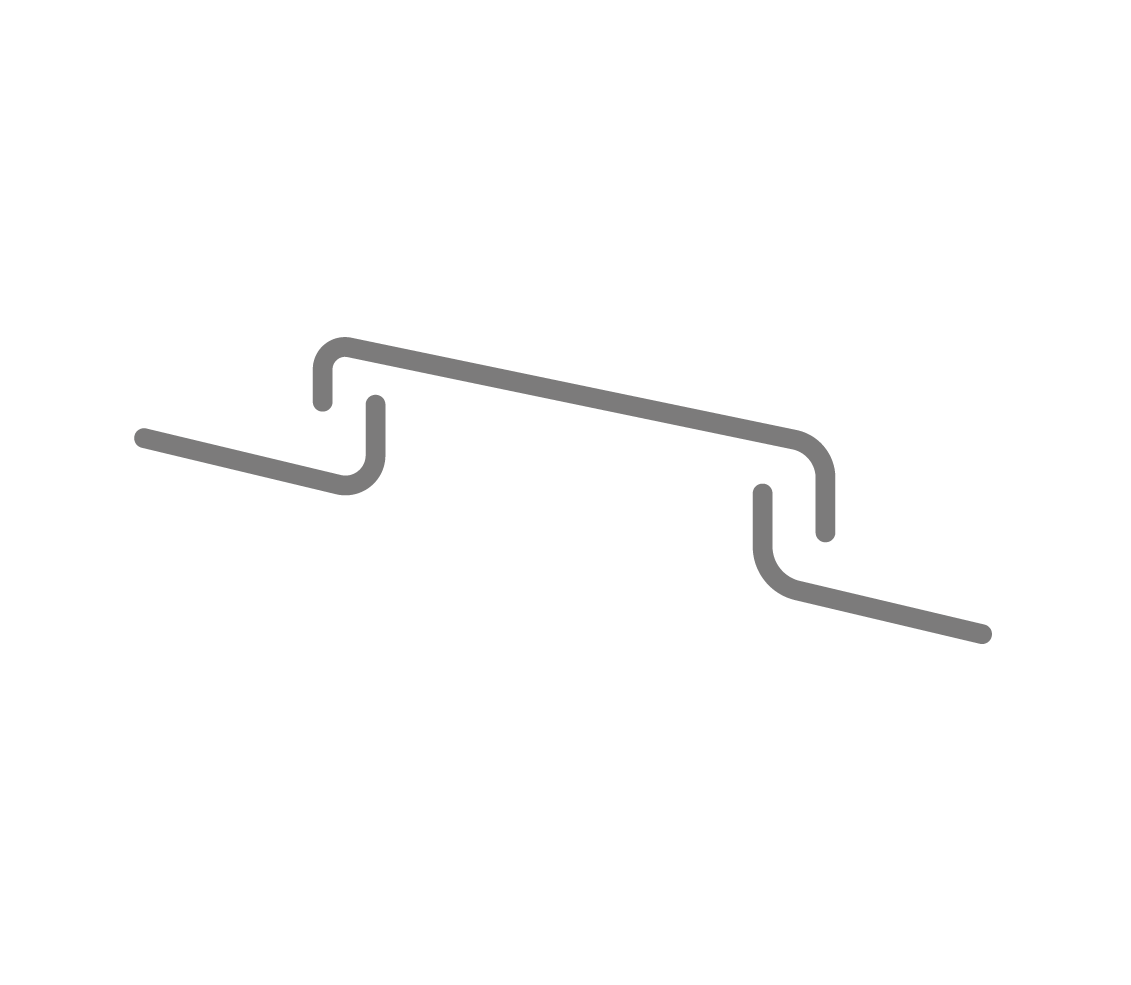

The floor slab features a flat intrados with a smooth metal formwork finish. It is produced in heights of 20 cm, 25 cm, 30 cm, 40 cm, 50 cm and 60 cm and has a lower layer with a thickness of 5 cm or 7 cm that houses the pre-stressing strands and five vertical ribs 12.5 cm thick and with height equal to the thickness of the slab.

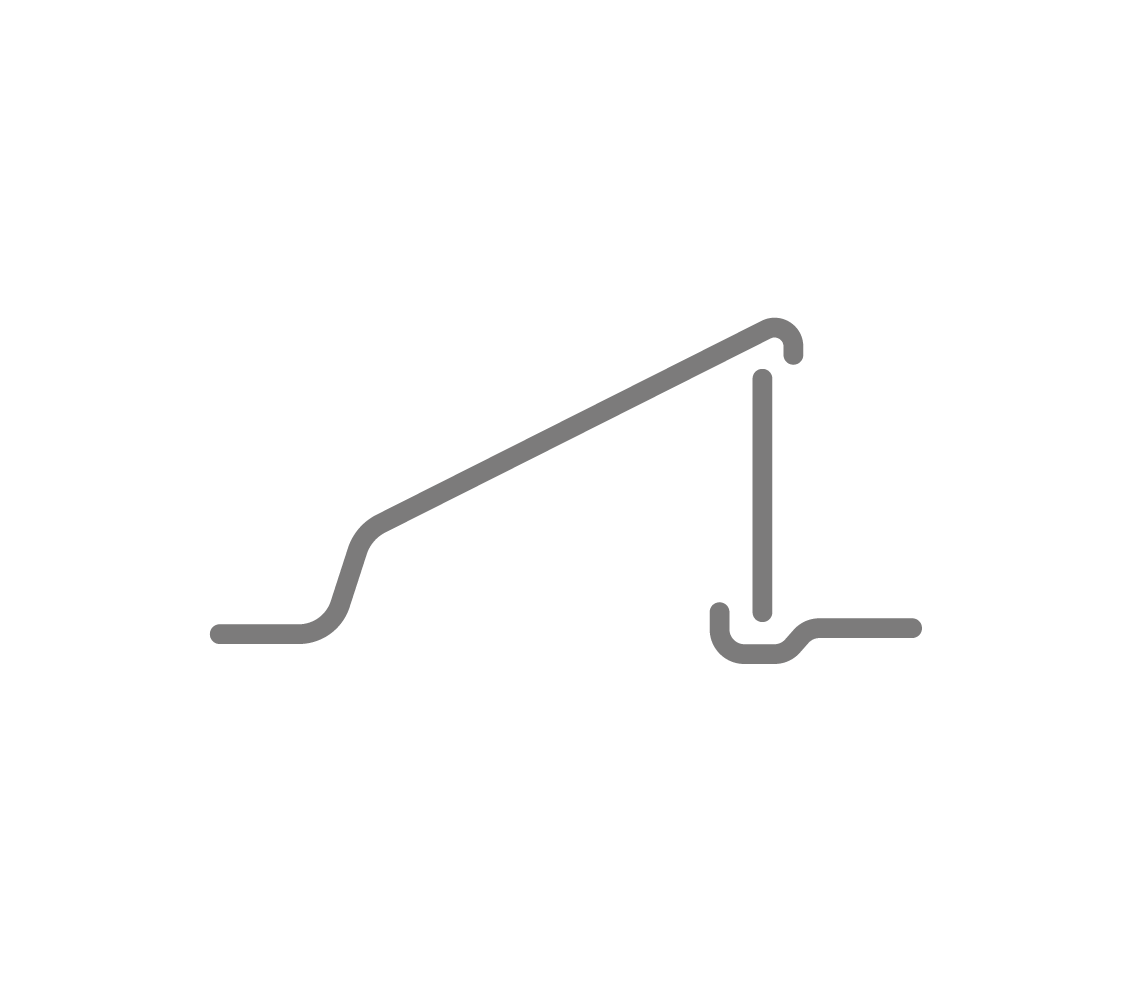

Light weight sandwich bricks of expanded polystyrene( EPS), produced in the factory, are placed between the ribs. The floor slab can be produced with an upper layer of 5 cm or with the EPS bricks exposed and protruding brackets for connection to the structural screed laid on top.

The roof slab system is completed on site by reinforced concrete castings with a thickness varying from 5 cm to 10 cm, which, in addition to improving the mechanical characteristics, fulfil the functions of load distribution and holding together the overall structure. The roof slab can be produced in widths smaller than the modular size of 250 cm and with variable lengths up to 12 m, depending on the specific project requirements, within the limits of structural feasibility, allowing ample flexibility in system dimensions.

The floor slab is designed for working loads usually between 4 kN/m2 and 20 kN/m2. It features high load-bearing capacities combined with reduced thickness, and is therefore particularly suitable for the construction of intermediate floors in office and residential buildings and buildings subject to crowding.

The EPS bricks inside the slab make it easy to insert the holes required for the interface with the building installations. It can also be produced with slanting ends and in irregular shapes in order to adapt to geometrically complex buildings.