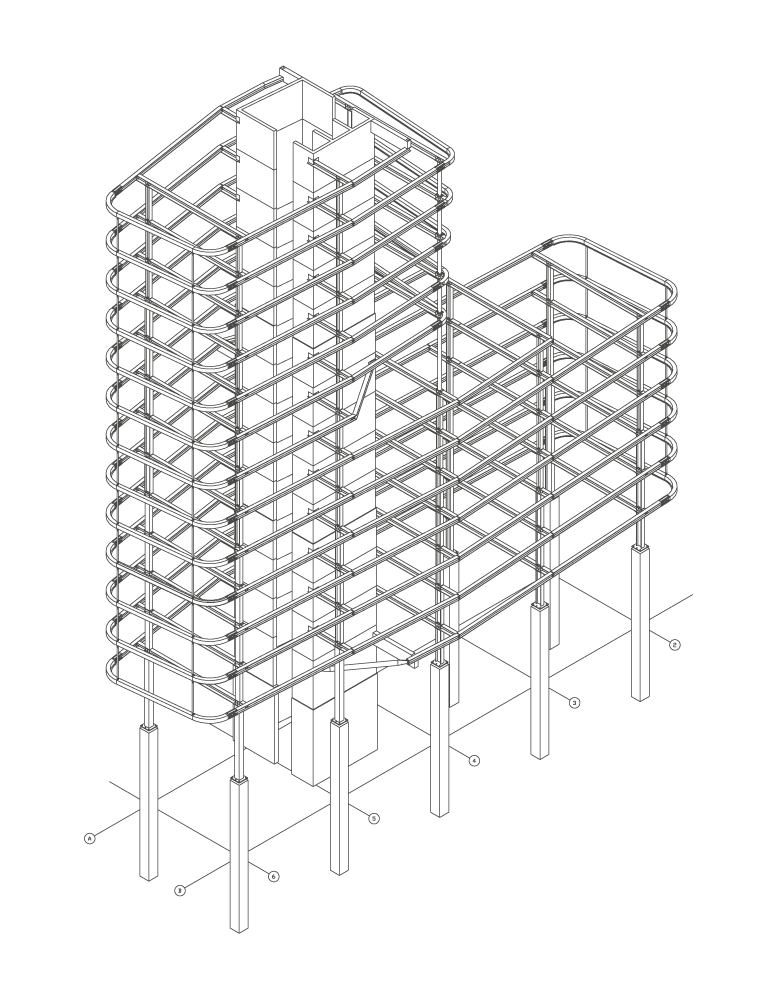

Approximately 5,500 m2 are reserved for high-value apartments and offices, featuring all the latest technical-functional solutions, spread across two towers, the tallest of which has 12 floors. Specifically for tower buildings, a composite floor solution of laminated wood and concrete was adopted: it involves entire wood panels, prefabricated and assembled in the factory and brought to the site, where they were installed and secured with an integrating cast.

Considering the location of the facility in a seismic zone, the technical office of Moretti Modular Contractor developed a system that uses two very special areoplastic material joints, with a capacity of about 40 t, which under instantaneous stresses do not move, but under enduring stresses, caused by seasonal temperature changes, they expand by 5-8 cm. This allowed the two lateral parts of the tower to be considered as a single block, resulting in significant economic and computational savings on the sections. TThe use of the laminated wood and concrete collaborating slab solution, in addition to ensuring great lightness (the floor, including beams, weighs only 180 kg/m2 allowed the work to be carried out in a very short time, with the guarantee of maximum quality.

Project: Eng. Simonetta Conter”