Completely earthquake-proof, the school hub housing about 900 students was built according to principles of energy self-sufficiency, thanks to the installation of photovoltaic panels and geothermal plant. The two internal macro-areas into which the new school hub is divided distinguish, while remaining connected, the more properly educational environments with the public spaces that can also be used by the entire citizenry: the former designed as separate and modular units developed around a central courtyard, the latter with public functions, realizing a connection with the city and usable for various activities even outside school hours. The entire building is entirely clad with a single ventilated facade system formed by surface panels of Botticino stone, while jutting frames in electro-colored aluminum define macro-figures that determine the different nature of the interior spaces.

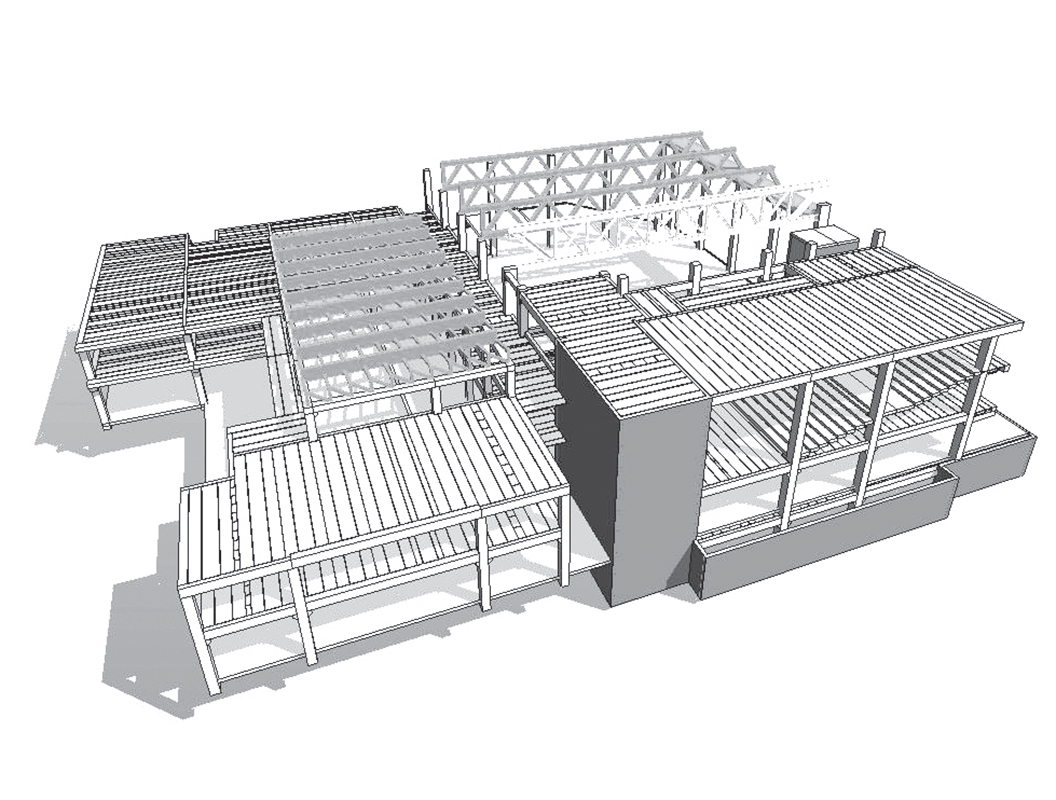

The structure built by Moretti Modular Contractor consists of 6,000 m2 of precast concrete deck elements. The inner finishing layer of prefabricated panels, assembled at the Erbusco plant, guarantees excellent acoustic performance, in favor of well-being and quality of living. To close the patio and gymnasium spaces, two glulam roofs were built. The first has a shed structure, which allows diffuse lighting with natural light that gives comfort and well-being to those who live in the space. The second, on the other hand, consists of special lattice girders 35 m long and up to 4 m high. The special location of the site and the characteristics of the project required special handling of these beams, which were pre-assembled in the factory in two portions, transported and jointed in place in the centerline. This process, which was also determined by the painstaking BIM design of the Moretti engineering department, maximized the quality of the elements produced at the plant and minimized construction time.

Project: Poolmilano SrL